UV LASER MARKING MACHINE

A UV Laser Marking Machine (Ultraviolet Laser Marking Machine ) is a high-precision laser system widely used for marking delicate or heat-Sensitive Materials. It utilizes a short-wavelength ultraviolet (typically 355nm) laser beam, which allows for “cold marking” -meaning minimal heat is transferred to the material, reducing the risk of damage or deformation.

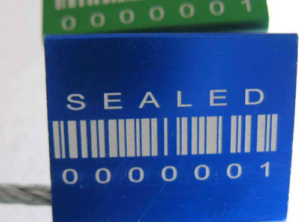

Ultra-fine engraving – logos, patterns, text, serial numbers, photos

Precision cutting – lightweight charms, pendants, bangles, and filigree designs

Works on gold, silver, copper, platinum, stainless steel, brass, and more

Non-contact, no tool wear – perfect for delicate and high-value items

High-speed operation with minimal material loss

Technical Specifications

| Specification | Details |

|---|---|

| Model | ALM-UV |

| Laser Type | UV Laser |

| Laser Wavelength | 355 nm |

| Average Output Power | 3W / 5W / 10W |

| Modulation Frequency Range | 20 kHz - 80 kHz |

| Maximum Speed | 7000 mm/s |

| Resolution | 0.001 mm |

| Re-positioning Precision | 0.003 mm |

| Marking Range | 110 x 110 mm or 200 x 200 mm |

| Minimum Line Width | 0.01 mm |

| Minimum Height of Characters | 0.2 mm |

| Cooling System | Water Cooling |

| Laser Power Supply | 0.5 KW / AC 220V / 50Hz |

| Environmental Requirements | 0-35°C, 90% Humidity |

Applications

UV laser marking machines excel at high-precision, cold marking on sensitive materials like plastics, glass, and electronics without causing thermal damage, makings and applications requiring minimal heat-affected zones in industries such as medical devices, pharmaceuticals, cosmetics packaging, and electronics manufacturing for product identification, traceability, and branding.