FLY LASER MARKING MACHIN

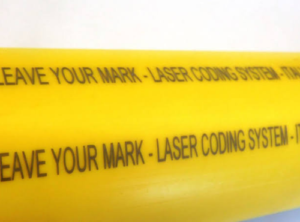

A fly laser marking machine is primarily used for high-speed, continuous marking on products moving along a production line, enabling efficient application of serial numbers, batch codes, date codes, barcodes, QR codes, logos, and other identifying or branding information in industries like industrial manufacturing, automotive, electronics, food and beverage packaging, pharmaceuticals, cosmetics, and materials processing such as extrusion and wire/cable production, offering benefits like increased throughput, permanent and precise marking, non-contact operation, versatility across materials, and seamless integration into automated systems.

Technical Specifications

| Specification | Details |

|---|---|

| Laser Power | 20W / 30W / 50W / 60W / 100W |

| Mode of Operation | Pulsed Laser |

| Laser Type | Fiber Laser (Raycus/Max/JPT/IPG) |

| Marking Speed | 12,000 mm/sec |

| Controller | High Resolution Scanner/Galvo |

| Wavelength | 1064 nm |

| Interface | USB / Ethernet |

| Fixtures | Nylon Fixture for Accurate Position |

| Cooling Type | Air Cooled with Panel |

| Operating Temperature AC | 24°C - 30°C |

| Z-Axis | Motorized / Manual |

| Dimension | 1600 x 750 x 750 mm |

| Encoder System | 1024 PPR Kubler (Made in USA) |

| Power Supply | 230V AC 50/60Hz - Single Phase |

Applications

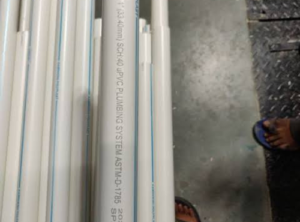

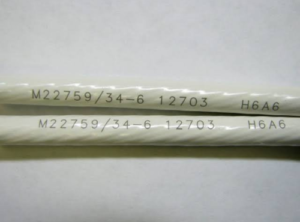

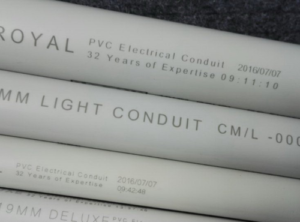

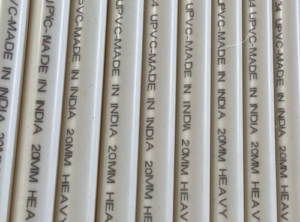

A Fly Laser Machine, also known as a Flying Laser Marking Machine, is a high-speed laser marking system designed for continuous, on-the-fly marking of products moving on a conveyor belt. It is commonly used in industries like packaging, electronics, pharmaceuticals, automotive, and food processing for marking barcodes, serial numbers, logos, and expiration dates on various materials.